Laser cutting is the most ideal technology for specialized high precision cutting requirements. Small surgical tubes are cut using the laser lights. They never make contact with the material and hence gives a sharp edges and patterns within the small boundaries. Most of the surgical equipment’s like blades, cutting tools and biopsy tools are cut using the laser cutting methods to give high precision as it has high focus points up to 25 microns.

We offer contract-cutting services on our state-of-the-art Laser cutting machine capable to cut up to 15mm Mild Steel, 8mm Stainless Steel, and 3mm Aluminium. Laser cutting gives a smooth finish and usually does not require any secondary machining of the cut parts. High accuracy of cut with tolerance of up to +/- 0.05mm can be achieved.

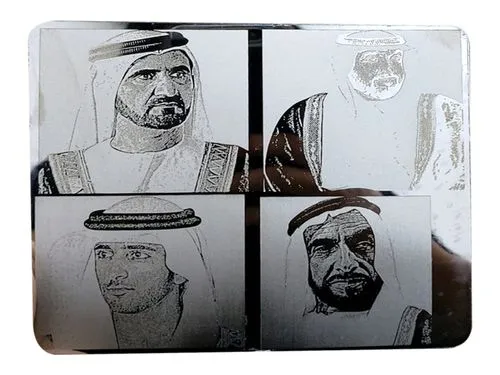

Laser engraving services include embossing, laser engraving, glass engraving, wood and gift engraving, etching, tablet engraving etc. Any smart cards available with the text, numbers engraved on it is done through laser engraving. Laser engraving technology is the safest yet personalized technology that cannot be erased or duplicated. We use high end machines with the state of art technology to carefully emboss personalized test on the material given. We handle any type of small and huge stock. Laser engraving so versatile that embossing can be done on any material given.

Computer numerically controlled (CNC) machines are used for controlling large machines through computer. CNC machines provide the most accurate bending for tubes and metal sheets. They are the best cost-effective option for 3D metal parts bending. These bent metals are used to form hydraulic press brake. CNC bending and forming gives high quality bending solutions and minimizes the risk of damage and improper fitting size.

All types of fabrication including metal fabrication like cutting, folding, machining, punching, stamping, welding prices are performed. Modern cutting methods provide the right cutting solution at a very low cost. Bending and folding are the most important process for any metal. Machining is the process of removing metal from any kind of material. This improves the quality of the material used to manufacture any object. Punching is the process of making holes on the metal sheets. Welding techniques are used to join two metals pieces during manufacturing process. We handle all types of fabrication methods according to the client needs.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Laser cutting gives a smooth finish and usually does not require any secondary machining of the cut parts.

Together with our CNC bending machine, we can do turnkey products as per the requirements of the client.

Our capability in fabrication is not limited in a box, we can do all types of products to match any specifications.

Send your inquiries through our website or email, give us a call, or visit our office.

We will provide you a quotation and discuss any other necessary details.

Once designs are finalized and agreed upon, we can work on the production.

We will ensure that the finished product will 100% comply with your specifications.

Elevate your moments with our laser-crafted perfection. Transforming ideas into timeless creations, one beam at a time.

LASER CRAFT INDUSTRIES LLC

49 14C St., Al Qouz Industrial Area 4

Warehouse No. 1, 5, 6 & 7

P.O. Box 34441

Dubai, U.A.E.

LASER CRAFT INDUSTRIES LLC

49 14C St., Al Qouz Industrial Area 4

Warehouse No. 1, 5, 6 & 7

P.O. Box 34441

Dubai, U.A.E.

All Rights Reserved © 2024 | Laser Craft Industries LLC